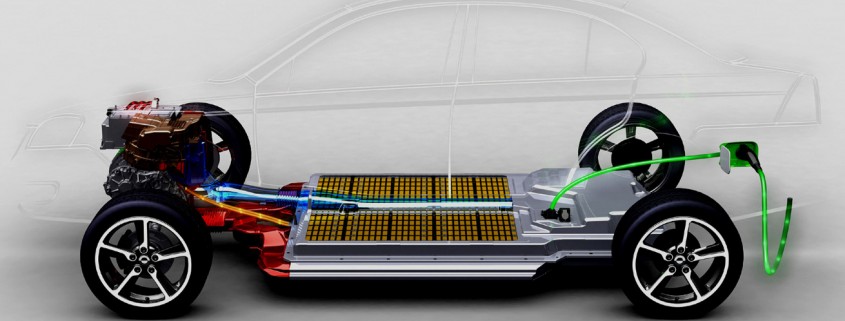

The batteries world is in constant change nowadays with the electric vehicles take off , the new and improved power storage, super capacitors, and the new kid on the block, graphene.

Lead batteries and AGM or gel are a thing of the past. We are now having the Li-ion present going to the new Li-air future.

The necessity of longer trips, fast charging times a better performance are a must in electric vehicles, and more and more, those demands are the big deal in EV.

Fresh air, still to come.

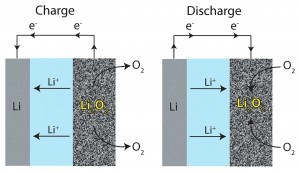

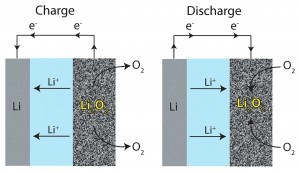

Till now, the obvious technology in the batteries department has been lithium-ion. But since some time ago, a new technology based in air is the real interest for manufacturers and EV developers. The new Li-air promises up to 10 times the energy density of their cousins li-ion. IBM´s project 500 has the aim of driving 500 miles in one single charge in a family car using those new batteries. Although this has been achieved already by the Metron Institute (Slovenia) with LiFePo4 technology.

The way it works is, a Li-air cell uses cheap carbon as a cathode (instead of cobalt), a molecule of a oxygen pivots through the cathode and gives the battery its name. But it has remained theoretical because of its big challenges. Among them: the other electrode in such batteries—the anode—is pure lithium metal, which provides a lot of energy but also ignites when exposed to water, carbon dioxide, or other contaminants.

Such is the challenge, that IBM and JCESR (Joint Center for Energy Storage Research) have decided to step back from the LI-air project, and IBM has turned his favour to a Lithium Sodium technology.

But with all these changes, a new development continues, and metal chemistries are also under development, in particular Aluminium-Air. An Israeli company (Phinergy), has claimed to solved corrosion, and recharging issues with a silver based catalyst. A prototype EV claimed to have 1600km range with Al-air batteries. However those cells cannot be electrically re-charged having to re-load them mechanically and topped up with water.

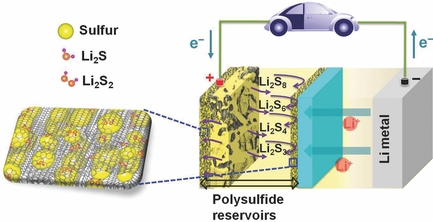

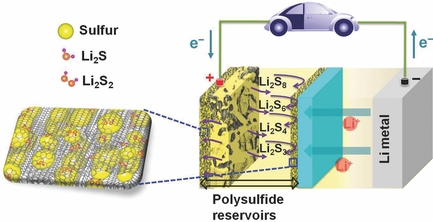

It smells sulphur.

Lithium Sulphur cells are another energy dense technology that could solve the needs for the EV in a near future. This new chemistry tends to solve issues like life cycle and stability. Based around a carbon based electrode, those cells are said they could go ahead Li-air technology.

Many studies and research from Imperial College (London) to German company BASF are putting their efforts into Li-S. They said this could be the 4th generation of batteries, expecting ranges of 400Kms in the next decade. Scientists at Lawrence Berkeley Labs (California) have introduced graphene oxide into Li-S cells that are said to deliver 1,500 charge cycles without deterioration.

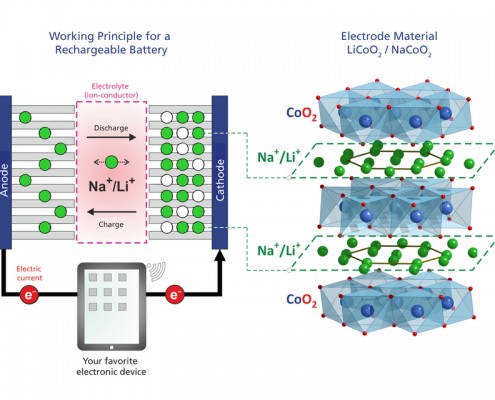

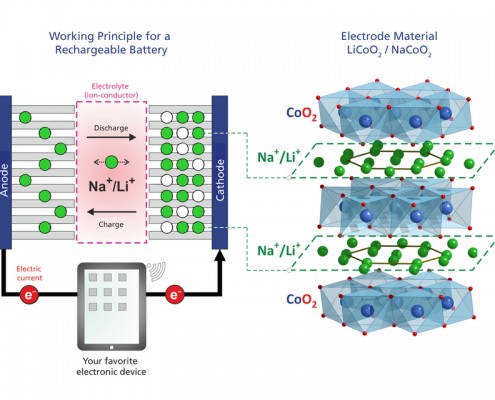

Other researchers from ETH Zurich are working with Sodium-ion cells, stating that are much cheaper than Li-ion. But they have two major problems; they are three times heavier than lithium and tend to lose capacity when not in use.

Lithium Ion are here to stay.

Despite all the development in the power storage field, one thing is clear, most of EV at the moment go for Li-ion, and the fact that manufacturer are offering cheaper prices and even Tesla is building a new Lithium batteries plant, makes you think that in the long term this technology is here to stay.

Li-Ion developers, Bosch, GS Yuasa and Mitsubishi, claim that the could reduce the prices to half in the Li-ion filed, and double the capacity, that would make EV much more approachable to normal consumers.

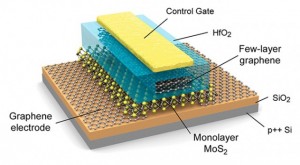

There are also many new promising developments with carbon, but the gap between the lab and the factories is too big to stop producing Li-ion for EVs.

The magazine “Electric & Hybrid Vehicle Technology International” writes in their July 2014 issue about the carbon:

“The real deal?. A new type of dual-carbon battery technology that could potentially be a game changer for EVs has been launched by a Japanese R&D company. Called Ryden, the new battery is said to offer energy density that’s comparable to Li-ion products, but over a much longer functional lifetime with far improved safety and cradle-tocradle sustainability, says Power Japan Plus, which will begin production of the cells later this year at its manufacturing facility in Okinawa, Japan. The Ryden battery makes use of a completely unique chemistry, with both the anode and the cathode made of carbon. “Power Japan Plus is a materials engineer for a new class of carbon material that balances economics, performance and sustainability in a world of constrained resources,” says CEO Dou Kani. “The Ryden dual-carbon battery is the energy storage breakthrough needed to bring green technology such as electric vehicles to mass market.” Kani says that the Ryden battery balances a breadth of consumer demands previously unattainable by a single battery chemistry. In terms of performance, the new battery is not only energy dense and operates at above four volts, but also offers a charge time that’s 20 times faster than that of current Li-ion designs.

The Ryden technology has been created so that it can slot directly into existing manufacturing processes, requiring no change to existing manufacturing lines. Furthermore, the battery enables consolidation of the supply chain, with carbon being the only active material used. As a result, manufacture of the Ryden battery is under no threat of supply disruption or price spikes from rare earth materials, rare metals or heavy metals. According to Power Japan Plus, its technology is the first high-performance battery that meets consumer cycle-life demands, being rated for more than 3,000 charge/discharge cycles. The breakthrough also eliminates the unstable active material used in other high-performance batteries, thus greatly reducing fire and explosion hazard. Furthermore, the new battery experiences minimal thermal change during operation, eliminating the threat of a thermal runaway. Finally, it can be 100% charged and discharged with no damage. Adding to the sense that the Ryden battery could be a key moment for EVs is that it is 100% recyclable, vastly improving the cradle-to-cradle sustainability of battery technology. As an add-on to this, Power Japan Plus is testing the battery with its organic carbon complex material, working toward the goal of producing the battery with all-organic carbon in the future. Made of naturally grown organic cotton, the carbon complex exhibits properties not seen in other carbon materials. By controlling the size of the carbon crystals during production, Power Japan Plus can engineer the carbon complex for a variety of applications.”

The Ryden technology has been created so that it can slot directly into existing manufacturing processes, requiring no change to existing manufacturing lines. Furthermore, the battery enables consolidation of the supply chain, with carbon being the only active material used. As a result, manufacture of the Ryden battery is under no threat of supply disruption or price spikes from rare earth materials, rare metals or heavy metals. According to Power Japan Plus, its technology is the first high-performance battery that meets consumer cycle-life demands, being rated for more than 3,000 charge/discharge cycles. The breakthrough also eliminates the unstable active material used in other high-performance batteries, thus greatly reducing fire and explosion hazard. Furthermore, the new battery experiences minimal thermal change during operation, eliminating the threat of a thermal runaway. Finally, it can be 100% charged and discharged with no damage. Adding to the sense that the Ryden battery could be a key moment for EVs is that it is 100% recyclable, vastly improving the cradle-to-cradle sustainability of battery technology. As an add-on to this, Power Japan Plus is testing the battery with its organic carbon complex material, working toward the goal of producing the battery with all-organic carbon in the future. Made of naturally grown organic cotton, the carbon complex exhibits properties not seen in other carbon materials. By controlling the size of the carbon crystals during production, Power Japan Plus can engineer the carbon complex for a variety of applications.”