When I had the idea of converting my own car to electric, I had two goals in mind. To be able to drive a novel car, that wouldn´t make any noise and the cost for the fuel be little or nothing. The other goal was to stop once for all contributing to dirt our environment and be able to tell the rest of the people “Yes, we can”, now days you also can have an electric vehicle exactly as it was at the beginning of the 20th century in New York (See the documentary “Who killed the electric car?” ).

When I had the idea of converting my own car to electric, I had two goals in mind. To be able to drive a novel car, that wouldn´t make any noise and the cost for the fuel be little or nothing. The other goal was to stop once for all contributing to dirt our environment and be able to tell the rest of the people “Yes, we can”, now days you also can have an electric vehicle exactly as it was at the beginning of the 20th century in New York (See the documentary “Who killed the electric car?” ).

Little by little, this idea was more and more real, asking other people, researching on the net and other countries where this was already a reality, I started the project of building an electric car.

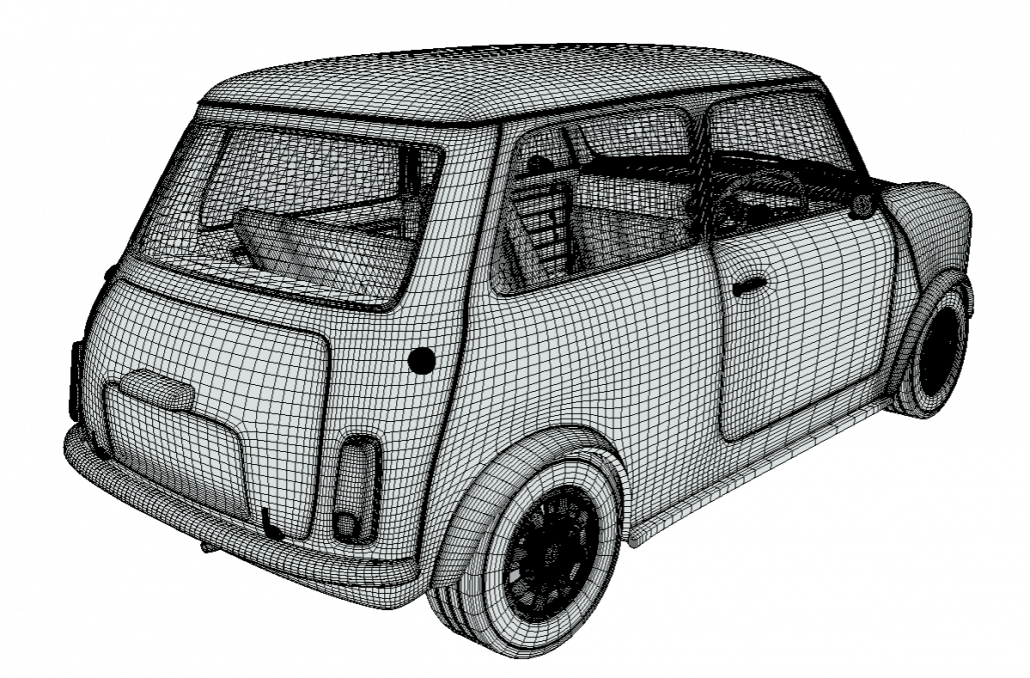

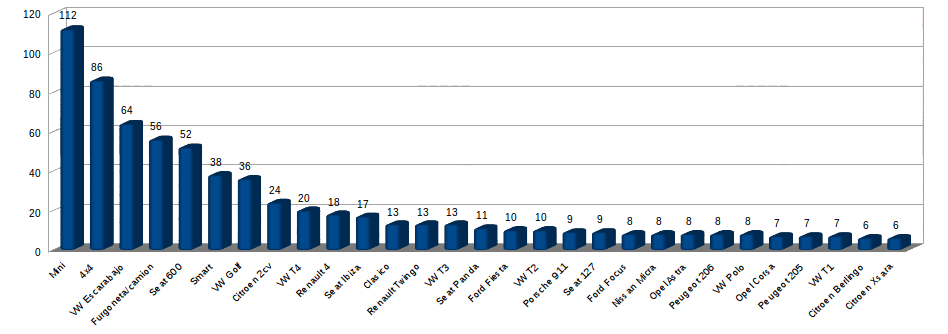

Choosing a donor car.

The first step, once everything is clear, was to choose a cheap car and appropriate for the project The best cars are old vehicles o classic cars. The reason for this is because they are not complex in their design and electronics are not playing an important role in the car functions. There is no need to be afraid at this point, nothing anyone can overcome reading a bit about the chosen car.

Another important requirement is the car to be light in weight, less than 1000 Kg is more than adequate, and 800Kg is ideal. The reason behind this is the resistance the car has because of the friction in the roads, the more resistance, the more electric energy it will need to drive.

Another important requirement is the car to be light in weight, less than 1000 Kg is more than adequate, and 800Kg is ideal. The reason behind this is the resistance the car has because of the friction in the roads, the more resistance, the more electric energy it will need to drive.

There is also other elements that a high speed affects the performance as the Aerodynamic coefficient, but this will leave it for the time being.

The old Renault Twingo is a car that weights very little, it doesn’t depends much on electronics (it doesn’t come with power steering or automatic gearbox). So I decided to get a cheap second hand Twingo and I spent 500€.

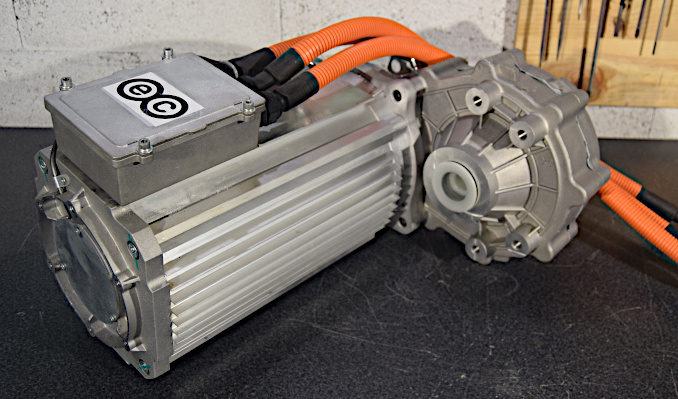

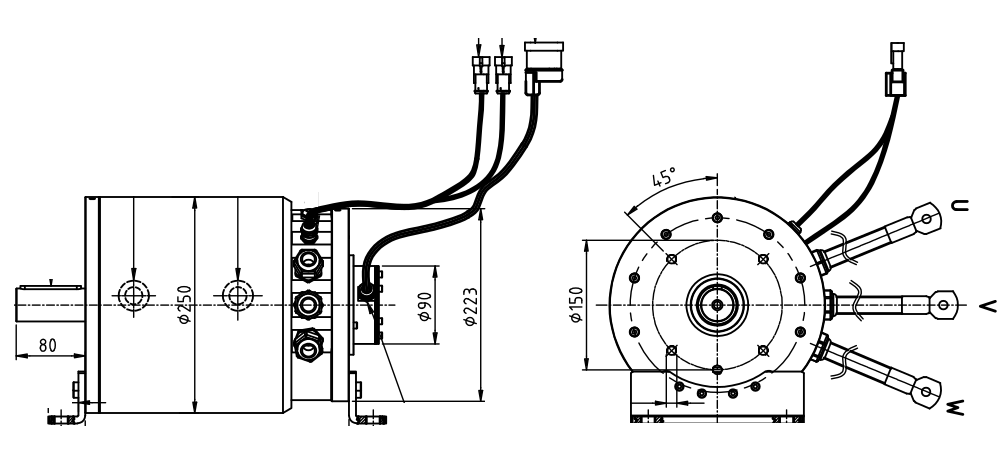

And now, the motor.

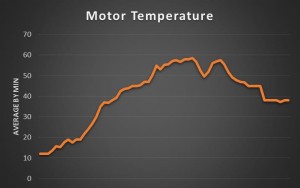

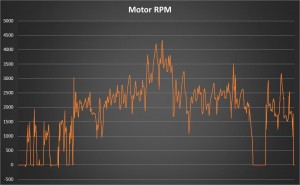

The motor is something you need to spend some time researching on it to take the correct decision. By choosing a small car, the motor doesn’t have to be very powerful, so a 7 to 15 Kw motor can be just perfect. There are two kinds of motors: DC motors (direct current) and AC motors (alternating current). The first ones are cheaper, more accessible in second hand markets or scrap yards, but they are less efficient. The second ones are more expensive; they weigh less and are more efficient. Then according to other technical aspects are synchronous motor and asynchronous, also other with permanent magnets, which supposed to be top of the list. As examples, there are 7 Kw motors from China that cost less that 1000€, while in Europe or USA you can have 15 to 25Kw motor between 2000 and 4000€. I decided to go for an Slovenian 14 Kw motor, branded Letrika. I knew this provider at the electric car fair EVS27 in 2013.

Motor electrico

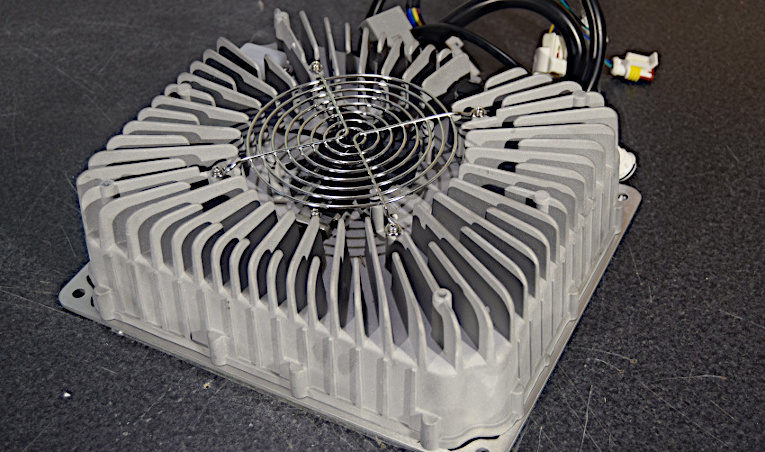

Lets go to the motor controller.

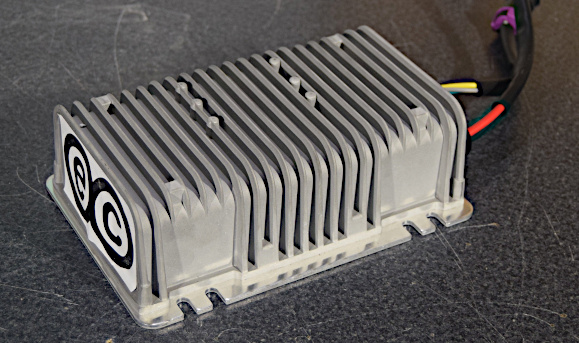

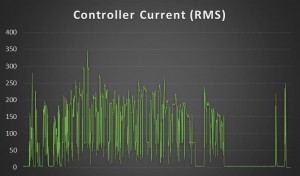

This is one of the main components, it is also one of the most expensive and it goes paired with the motor for two reasons: One, it is the one in charge to convert the batteries electric power to the correct voltage necessary for the motor, and the second, to regulate the speed of the motor, so the controller needs to be designed for it. As with the motor, there are DC controllers and AC controllers. The good news is that most of the motor manufacturer they also do the controllers, and if the don’t, normally the motor can be configured for generic configurable controllers.

Controllers are also classified according to the maximum current they can feed, the more current and voltage, the more powerful l the motor will be. There are several brands as Brusa, Curtis, Sagem, ..

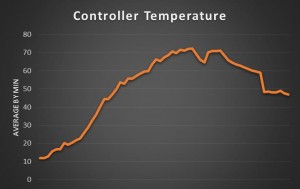

I got a Curtis controller, medium range for AC motor, the Curtis controller 1236. Most of the controllers are programmable, so you can adapt it to your own motor. You will have to study a bit about variety and features of the controller best suits you.

I got a Curtis controller, medium range for AC motor, the Curtis controller 1236. Most of the controllers are programmable, so you can adapt it to your own motor. You will have to study a bit about variety and features of the controller best suits you.

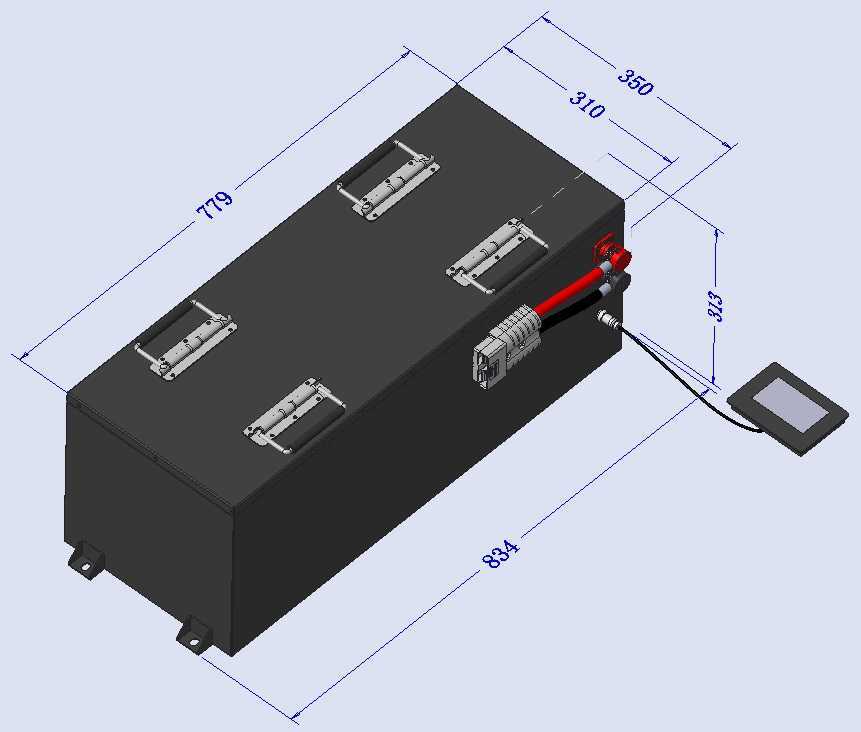

And we get to the batteries, the queens.

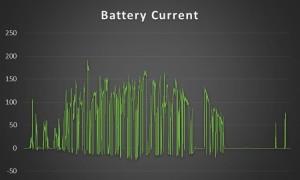

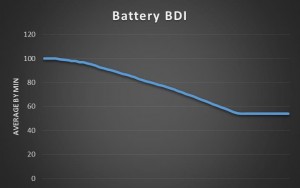

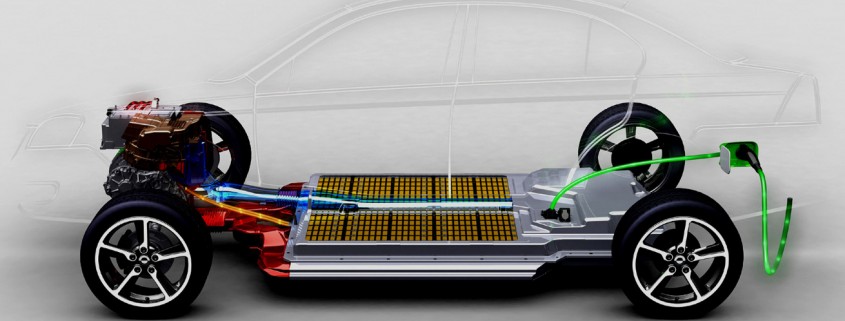

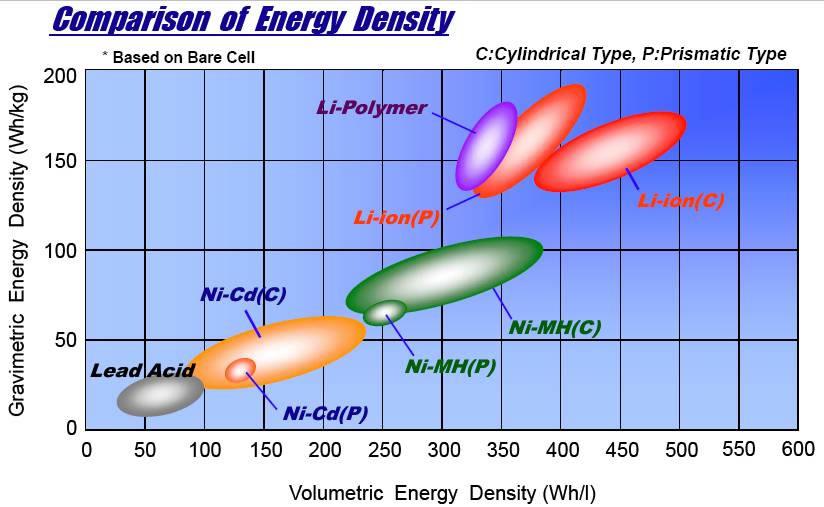

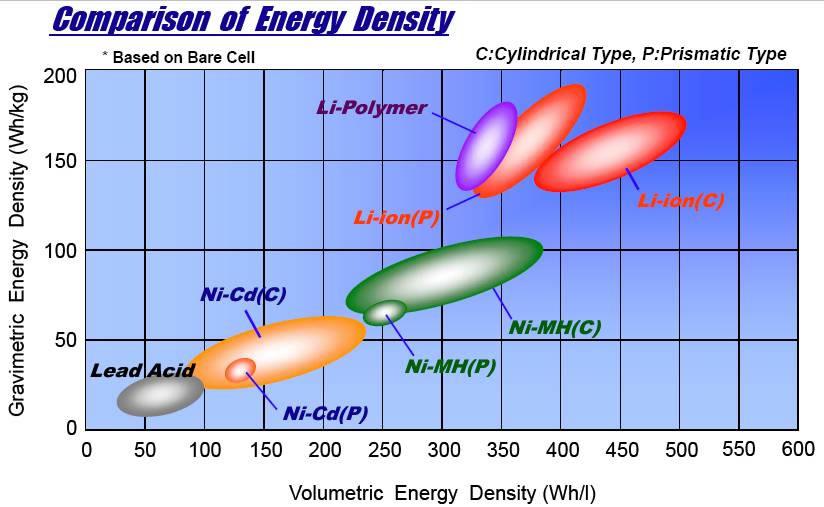

Batteries are the most important element in a electric vehicle, as they will define how much power and how much range the electric car will have. I hope one day this element will be the less important, but for the time being, this technology is more complex than we may think. The appropriate batteries bank is conditioned by the maximum distance the car will drive in one single char and also the charger and the BMS (Battery Management System). Not all kind of batteries can be charged or discharged in the same way, if you don’t follow the manufacturer requirements and limits, batteries can be affected and their life span be reduced.

There are several technologies in the market right now, but in practical terms we can talk about 3 or 4 types. Lets start by the cheap ones.

Lead Batteries. They are the cheapest ones, but the least suitable ones because its design, as they are not design to provide a constant current all the time, but to provide a very strong one in one go, and this is not what a controller for a electric motor needs. The good news for a budget car, is that even dead, you can re-acconditionate them or de-sulphate them. This is a delicate process as the content inside the batteries is sulphuric acid, so if you are a bit un-sure of what you are doing, better not to try. I have done it being very careful, and following all the security precautions and using protecting gloves, glasses and mask (in an open environment), at the end you need to neutralize the acid with sodium bicarbonate before wasting it to the sink. You can also buy them to avoid all this hassle. They are very heavy, but can be charged with any standard charger.

Lead Batteries. They are the cheapest ones, but the least suitable ones because its design, as they are not design to provide a constant current all the time, but to provide a very strong one in one go, and this is not what a controller for a electric motor needs. The good news for a budget car, is that even dead, you can re-acconditionate them or de-sulphate them. This is a delicate process as the content inside the batteries is sulphuric acid, so if you are a bit un-sure of what you are doing, better not to try. I have done it being very careful, and following all the security precautions and using protecting gloves, glasses and mask (in an open environment), at the end you need to neutralize the acid with sodium bicarbonate before wasting it to the sink. You can also buy them to avoid all this hassle. They are very heavy, but can be charged with any standard charger.

AGM or gel batteries. Those are deep cycle batteries, they are lead batteries with more efficient electrolyte gel. They are a bit more expensive but they are designed for electric cars. They are very heavy too, and there are manufacturer that assure up to 1000 cycles before losing charge capacity. The charger has to be specially design for gel batteries to follow a correct charge parameters for gel or AGM. They are not very expensive, I bought 6 of them, 12V at 100Ah for about 900€.

AGM or gel batteries. Those are deep cycle batteries, they are lead batteries with more efficient electrolyte gel. They are a bit more expensive but they are designed for electric cars. They are very heavy too, and there are manufacturer that assure up to 1000 cycles before losing charge capacity. The charger has to be specially design for gel batteries to follow a correct charge parameters for gel or AGM. They are not very expensive, I bought 6 of them, 12V at 100Ah for about 900€.

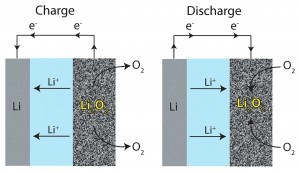

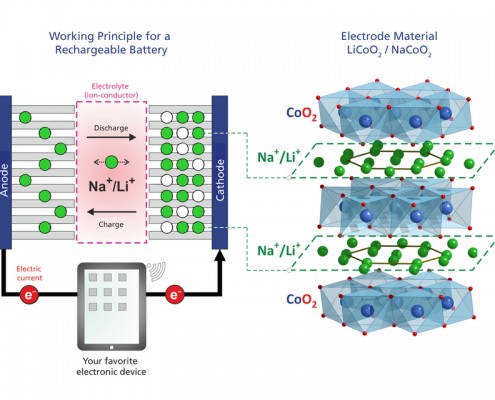

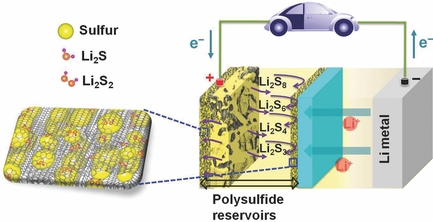

Lithium batteries. This already more expensive, but they weight about half and they have double capacity. Those are the standard option for electric cars. They use to come in 3.7 cells, so you have to get many of them to achieve the desire voltage. Another VERY IMPORTANT issue is that lithium batteries need to be managed (charged and discharged) by a BMS (Battery Management System). The reason is that these batteries cannot be charged or discharged outside the recommended limits by the manufacturer. As an example, 18650 lithium cells can only be charged at a maximum of 4.1V and discharged at a minimum of 2.5V.

Lithium batteries. This already more expensive, but they weight about half and they have double capacity. Those are the standard option for electric cars. They use to come in 3.7 cells, so you have to get many of them to achieve the desire voltage. Another VERY IMPORTANT issue is that lithium batteries need to be managed (charged and discharged) by a BMS (Battery Management System). The reason is that these batteries cannot be charged or discharged outside the recommended limits by the manufacturer. As an example, 18650 lithium cells can only be charged at a maximum of 4.1V and discharged at a minimum of 2.5V.

– Pyrophosphate batteries (LiFePO4). They are the most expensive of all but also they have the more energy capacity.

Enough batteries for now..

Another very important component is a current converter for high voltage to 12V.

Another very important component is a current converter for high voltage to 12V.

When we remove the IC engine (Internal combustion), one of the components that also disappears is the alternator, the one in charge of keep the battery always at the proper voltage (in this case we could call it the auxiliary battery) for lights, electric windows, radio, etc. So, as the alternator is missing, we need a system have it always charged, for example, a DC converter 72V to 12V.

Well, that´s it, isn’t ?. No, still something important, the brakes.

For the brakes, you need to supply the vacuum that the IC engine use to make for the brake booster. So we need to install a vacuum pump in order to replace the missing one in the IC engine.

Then you need other small components, but equally important as a pedal accelerator, a contactor, some relays, fuses, etc.

Those small components are as relevant as the big ones, because even with the motor and controller, with no cables, there is no use. Also, you need to see the high voltage requirements that the motor manufacturer recommends. Also the signal cables are also important in following no just the diameter but the isolation.

Now the adventure starts… just install everything in the car.

If you are interested in converting your car to electric and need more information, support, documentation or just someone who share your hobby, you can contact with us by clicking here.